Large Scale Additive Manufacturing (LSAM) industrial 3D printing

Additive manufacturing continues to develop as a production method. CEAD is also continuously working on new large scale additive manufacturing solutions, both robot based as well as gantry based large scale additive manufacturing solutions.

This page answers the most important questions concerning large scale additive manufacturing, such as ‘what is LSAM’, ‘what are the different types of LSAM’ and ‘what are the benefits of LSAM’. Furthermore, CEAD’s large scale additive manufacturing solutions are highlighted.

What is LSAM?

Lets first get to the essence: what is Large Scale Additive Manufacturing (LSAM)? The definition can be broken down into multiple concepts. In short: Large Scale Additive Manufacturing (LSAM) relates to the use of large industrial 3D printers that are used to create workpieces by polymer extrusion. There is no difference between LSAM, LFAM or large scale 3D printing, only the name is distinct.

Let’s get deeper into the definition of LSAM. The first part of the term, Large Scale, relates to both the large format of the 3D printer as well as the size of the printed objects. This means that large printers are able to print large workpieces. Examples of these workpieces are automotive molds and even 3D printed bridges.

The final section of the term, Additive Manufacturing, refers to the process of constructing workpieces layer by layer. 3D printing is an example of additive manufacturing. During additive manufacturing, polymer is extruded on top of a previous layer of polymer, resulting in layered structures. The opposite of additive manufacturing is subtractive manufacturing.

What are the different types of LSAM?

Large Scale Additive Manufacturing does not have a ‘one-size-fits-all’ approach. CEAD has, for example, different lines of LSAM solutions for industrial 3D printing. These solutions can be divided into robot based, gantry based and technology components, such as robot extruders. The solutions match the needs of industrial applications and therefore differ between them.

When deciding between a robot based system or a gantry based printing system, all of the factors that will influence the printing system have to be taken into account. The best solution for large scale 3D printing thus depends on the application itself.

Robot based LSAM

Large Scale Additive Manufacturing through robotics has several advantages. First of all, generally speaking robot based LSAM provides more flexibility than gantry systems. It is also easier to add additional modules to the machine in a later stage. There are also more opportunities for relocation, because of the decreased weight of the robot compared to a gantry solution.

CEAD’s robot based LSAM solution is the AM Flexbot. This versatile and modular system provides lots of options which can be integrated to configure the system to your specific needs. The AM Flexbot can easily be extended with additional functions such as a rotary table, additional robots or other production processes such as CNC milling but also other processes. This system has proven itself to be the go to system for large scale 3D printing implementations in the industry. The system is delivered and installed worldwide. Read more about the AM Flexbot.

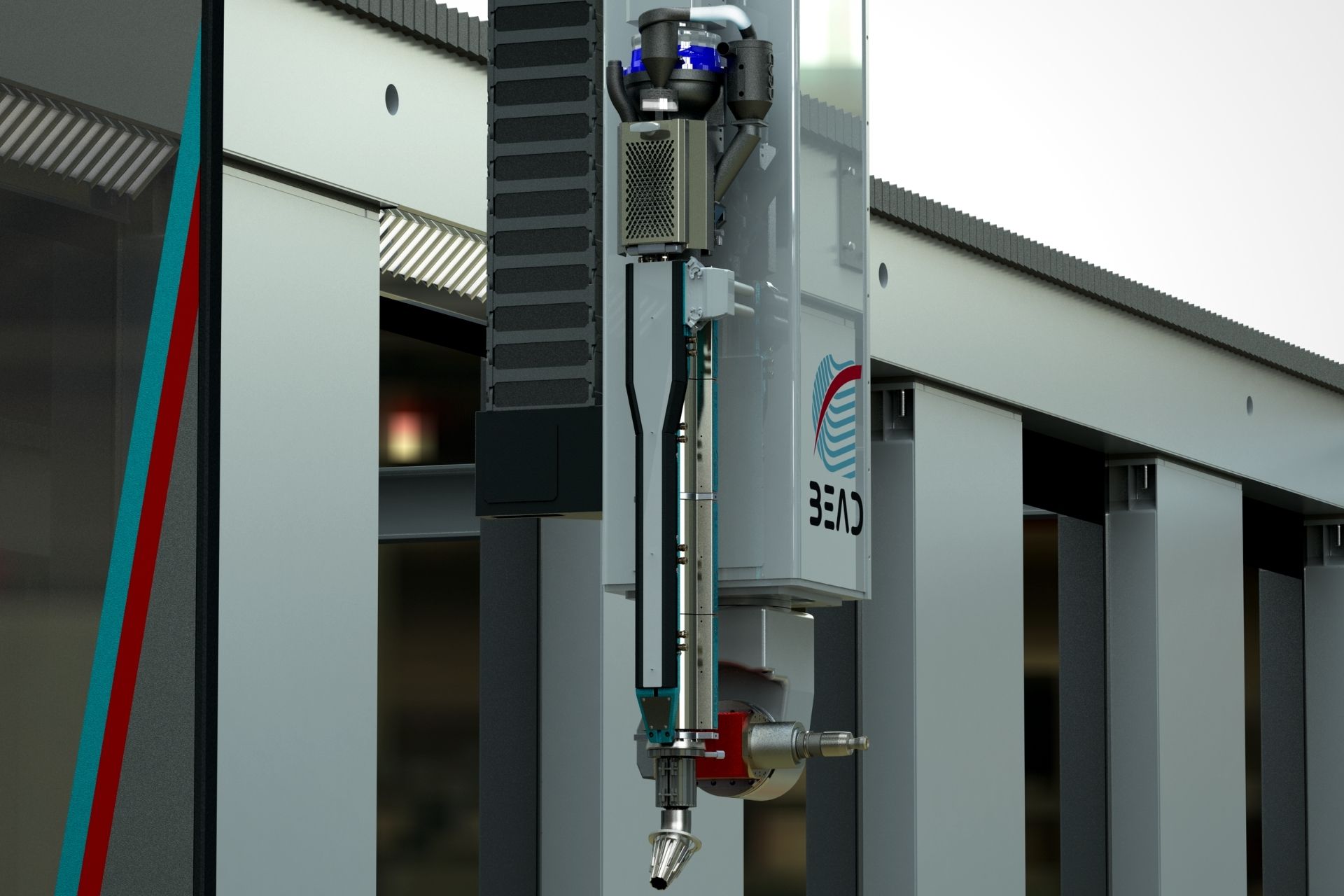

Gantry based LSAM

The other side of the spectrum consists of gantry based Large Scale Additive Manufacturing solutions. Generally speaking, gantry based solutions are larger than robot based ones. While this results in less freedom of relocation and more restrictions for buildings, it also means more accurate printing and provides higher printing speeds.

CEAD’s gantry based LSAM system is the result of a strategic worldwide partnership between Belotti S.P.A. and CEAD, in which the expertises of both branches are combined. The BEAD is a hybrid solution, combining the finish and tolerances subtractive manufacturing offers with the sustainability of additive manufacturing into one system. The BEAD gives the best of both worlds: making it possible to 3D print the near net shape of a part and afterwards milling it to the required tolerances with a CNC milling machine.

What are the benefits of LSAM?

Large scale additive manufacturing provides an alternative for traditional manufacturing methods, such as injection molding. Below are the main advantages of LSAM summarized:

- Sustainable production: large scale additive manufacturing allows materials to be reused in future prints.

- Less material waste: traditional injection molding wastes a lot of material, LSAM only uses material for the workpiece.

- Easier prototyping: if you can design a prototype, you can print it. Large scale additive manufacturing is the perfect production method for prototyping.

- Produce smaller quantities: related to prototyping, it is fairly cost-effective to produce small quantities with LSAM.

- Improve designs: are you not satisfied with a design? Simply redesign and print it again.

More information on LSAM

CEAD is a technology supplier of 3D printing equipment on the frontier of large scale composite additive manufacturing. With passion for technology and innovation, we are driven to find creative solutions for our clients and their applications. Helping them to transform their business activities with our technology.

We are happy to inform you about the possibilities of LSAM for your company. Please feel free to contact us for more information.