The complete package of CEAD solutions for industrial 3D printing consists of seemingly similar products. However, the unique characteristics of our three types of large scale 3D printers ensure that the various solutions fit distinct applications. This blog provides insight into the selection between our pellet extruders, robot based solutions and gantry based solutions for large scale 3D printing by highlighting their specifications. Do you need tailored advice on the optimal system for industrial 3D printing for your application? Do not hesitate to contact us.

1. Pellet extruders for large scale 3D printing

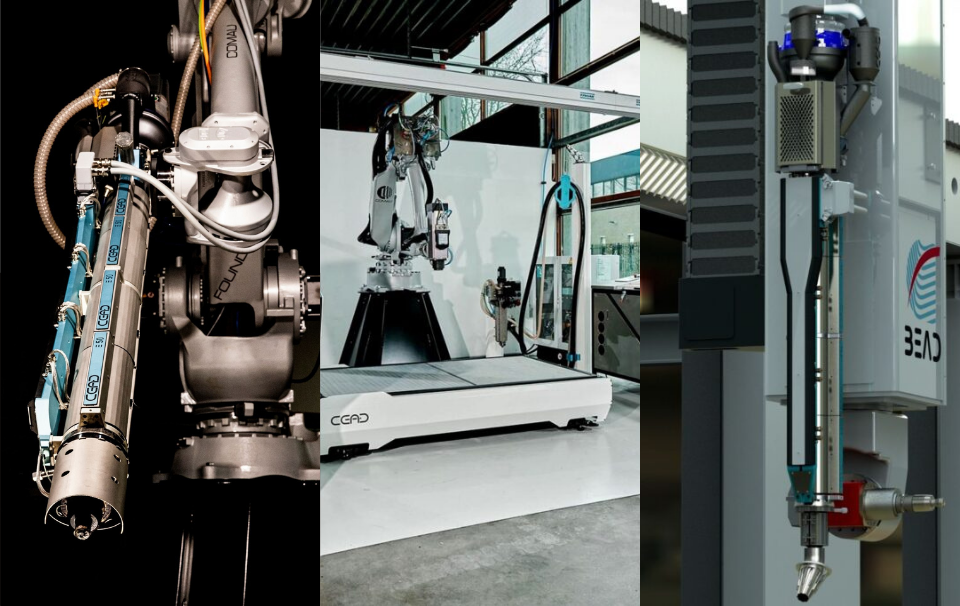

The first section of CEAD’s solutions for industrial 3D printing consists of our pellet extruders, which are provided separately from a robotic system as a modular print head. In this way, the print heads can be integrated into an existing machine. This ensures high flexibility for the pellet extruders as well as a low financial investment compared to complete solutions such as gantry based or robot based solutions.

In practice, pellet extruders offer the perfect opportunity for existing manufacturers to take the first step into large scale 3D printing. However, a separate print head could provide less precision as opposed to a complete gantry based or robot based system.

Printing head E25 and E50

CEAD installed its first pellet extruders, the E25, three years ago. The first printing head provided the solution for a stand-alone print head dedicated for large scale 3D printing with a maximum of 12 kg/hr. Client feedback since then provided an insight into an existing demand for higher material output. This demand is matched with our recently launched E50, which has an output of over 84 kilograms/hour.

Would you like to acquire more information on our pellet extruders? You can find more information on printing heads for large scale 3D printing on our website or by contacting us directly!

2. Robot based large scale 3D printing solutions

A more advanced and complete solution for large scale 3D printing can be found in our robot based Flexbot. This versatile system provides a flexible solution for specific needs. The Flexbot provides a complete solution, including CEAD Pellet Extrusion technology, a Comau robot, Siemens Sinumerik 840D, working table(s) and, a safety cage.

One unique feature of this robot 3D printer can be found in the Siemens Sinumerik software which is used to directly control the robot arm. This ensures that the robot and the extruder – and even more axes are possible – are realtime controlled through the same controller. Additionally, no external robotic language is necessary for the operation, standard G-codes are used. Making it easy in use and more accurate along the toolpath.

In addition to the use of pellet extrusion, the Flexbot is able to combine 3D printing and milling into one automated process. This, combined with the characteristics of the Flexbot make this solution highly suitable for those that require an assembled and complete 3D printer pellet extruder with high flexibility.

The Flexbot systems are available in different setups, for example a track can drastically enlarge the build volume. However there are limitations, the building dimensions for the Flexbot start at roughly 2m x 1m and can go up to 8m x 2m. Looking for a larger print area? Then the gantry based system is the solution you are looking for.

For more information on the Flexbot, read more on our robot based 3D printing solutions, download the brochure or contact us.

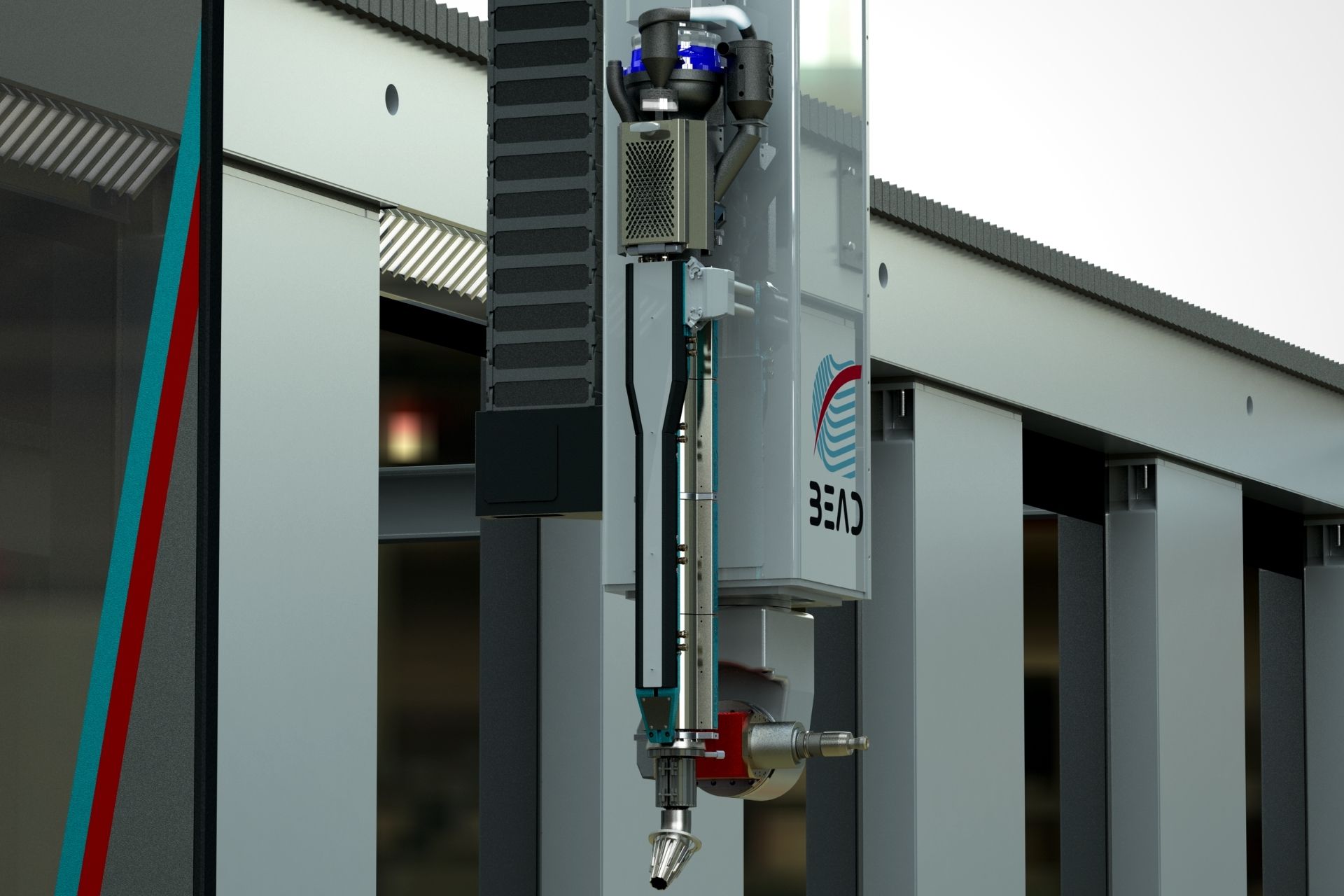

3. Gantry based large scale 3D printing solutions

The final section of our solutions for large scale 3D printing consists of two gantry based solutions for 3D printing: the BEAD and the CFAM Prime. These gantry based 3D printers provide an even bigger build envelope for pellet extrusion. The rigid construction provides higher accuracy, which makes it ideal for milling operations where high precision is required. Besides higher accuracy, higher speeds can also be achieved with the gantry based solution.

In practice, gantry based solutions are applied in, among others, the aerospace industry and the maritime sector because of the combination of high accuracy and large print possibilities.

BEAD

Our most recent gantry based industrial 3D printer is the result of a strategic worldwide partnership with Belotti S.P.A., combining the expertise of both branches. The result is a hybrid solution for high precision additive manufacturing that is able to deliver the finish and tolerances that subtractive manufacturing offers.

Click to read more on our gantry based solutions for large scale 3D printing.