Pilot Project

To assess the technical and commercial feasibility of the application using large scale 3D printing, a pilot project can be conducted together with CEAD. During this project we will investigate important aspects of the application such as the design, required material, and printing strategy. Pilot projects are always customized to your needs. The project is typically ranged in between a material test or a full scale end use part.

Minimizing risk with 3 phases

A larger Pilot Project typically consists of three phases deliberately in place to minimize the risk for both parties. Every phase ends with a Go/No go moment which allows both parties to control the project. Each phase assesses vital parts of the technical and commercial feasibility of the case. Smaller Pilot Projects are often executed in one phase.

Pilot projects consist of a quick analysis, an in depth analysis, and the actual pilot project itself. Each of the three phases assesses a vital part of the technical and commercial feasibility of a case study. Below the three different components of a pilot project are elaborated on.

Phase 1: Quick analysis

The first step of larger pilot projects consists of a cost-effective quick analysis into the overall difficulty of the project. The complexity, object size, and material selection are taken into account during the quick analysis. Furthermore, the characteristics of the part itself are of importance in this phase. We distinguish three types of parts: a mold, a structural part, and a non-structural part.

The first output of the analysis is used to form a general idea of the project plan, including the required 3D printing system, and a cost estimation. Before additional in depth analyses are conducted, the cost estimation of the pilot project itself can be used to assess the importance of further steps. The cost estimation combined with the difficulty of production provides the input for the first go/no-go moment. Once both parties decide to continue with the project, the second phase is started.

Phase 2: In depth analysis

The pilot project continues with a more detailed and technical analysis. The requirements analysis takes external factors into account, such as corrosion or chemical resistance. Additionally, various 3D print strategies, redesign analysis, and material selection are extensively reviewed during this stage.

During this analysis, a general layout of the project plan is formed as well as a rough estimation of lead time. The project plan provides an overview of the steps required for the project to succeed. This information provides the CEAD specialists the possibility to calculate the future hourly costs for in house printing. Finally, the in depth analysis concludes with a second go/no-go moment.

Phase 3: Pilot project

The third part of the project consists of the actual pilot project itself. During this step, CEAD helps to create the business case. This is done through a refinement of the in depth analysis. Cooperatively, we locate areas for possible improvements and make small adjustments to the project. Think for example of the definite selection of material, a redesign of parts and testing of critical points, such as a material test and a tensile test.

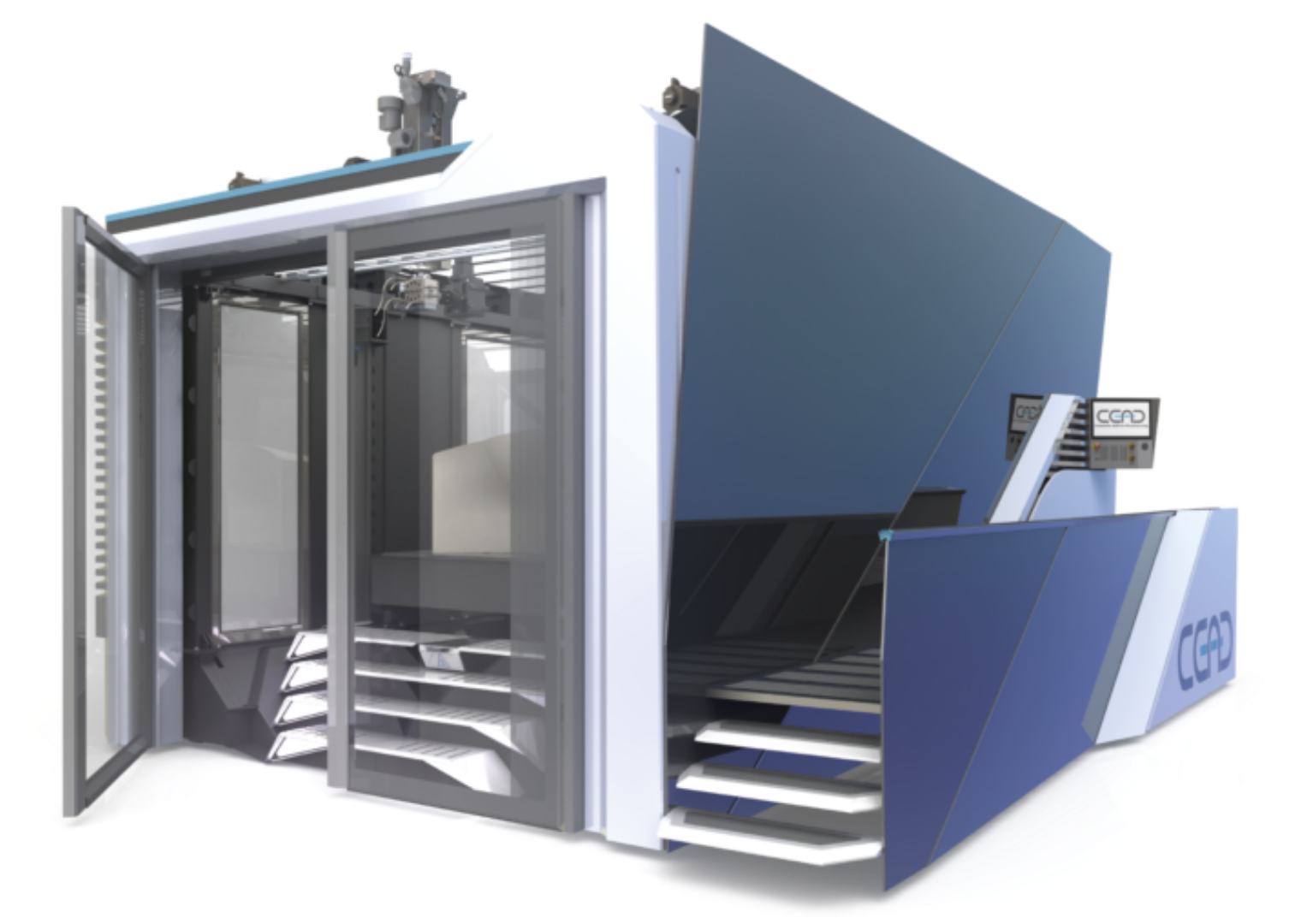

The final product of the pilot project can be found in the demonstration of the technical feasibility, by printing and milling the complete part. This proof of concept is then used to assess the commercial feasibility of the project, followed by the final go/no-go moment. If the pilot project is concluded successfully, the actual purchase of the selected large scale 3D printer can start.

Start a pilot project

A pilot project can give your organization answers on questions concerning large scale 3D printing, such as the cost and technical feasibility. The modular layout of the pilot project combined with the various go/no-go moments ensures that only required steps are taken, minimizing risks for both parties.

Curious about more information on a 3D printing pilot project for your organization? Please feel free to contact us directly at info@ceadgroup.com, +31(0)15 737 01 83 or through the contact form below.

Pilot Project: Large-scale 3D printed bridge

For this project, three companies joined forces to break new ground: CEAD, international engineering and project management consultancy Royal HaskoningDHV, and DSM: an international company focussing on developing game-changing scientific science across multiple societal areas.

Robot Extruder E25: 3D printed molds with Polypropylene 30% short glass fibers

Rapid Prototyping is an Hungarian based large-format prototype manufacturing company with over 20 years of experience in the industry. With their CNC-machine, they build molds for the yacht industry, maritime industry, custom trucks manufacturers, and other related industries.