In order to unlock the full potential of our solutions, one must be familiar with the possibilities of large scale 3D printing. This is why CEAD helps clients with personalized training, both in-house at our production hall, as well as on-site at your production facility. Training is provided to obtain the knowledge and skills required to operate a specific 3D printing machine that was purchased. This article elaborates on the different possibilities for training that are offered by CEAD.

What are the training possibilities?

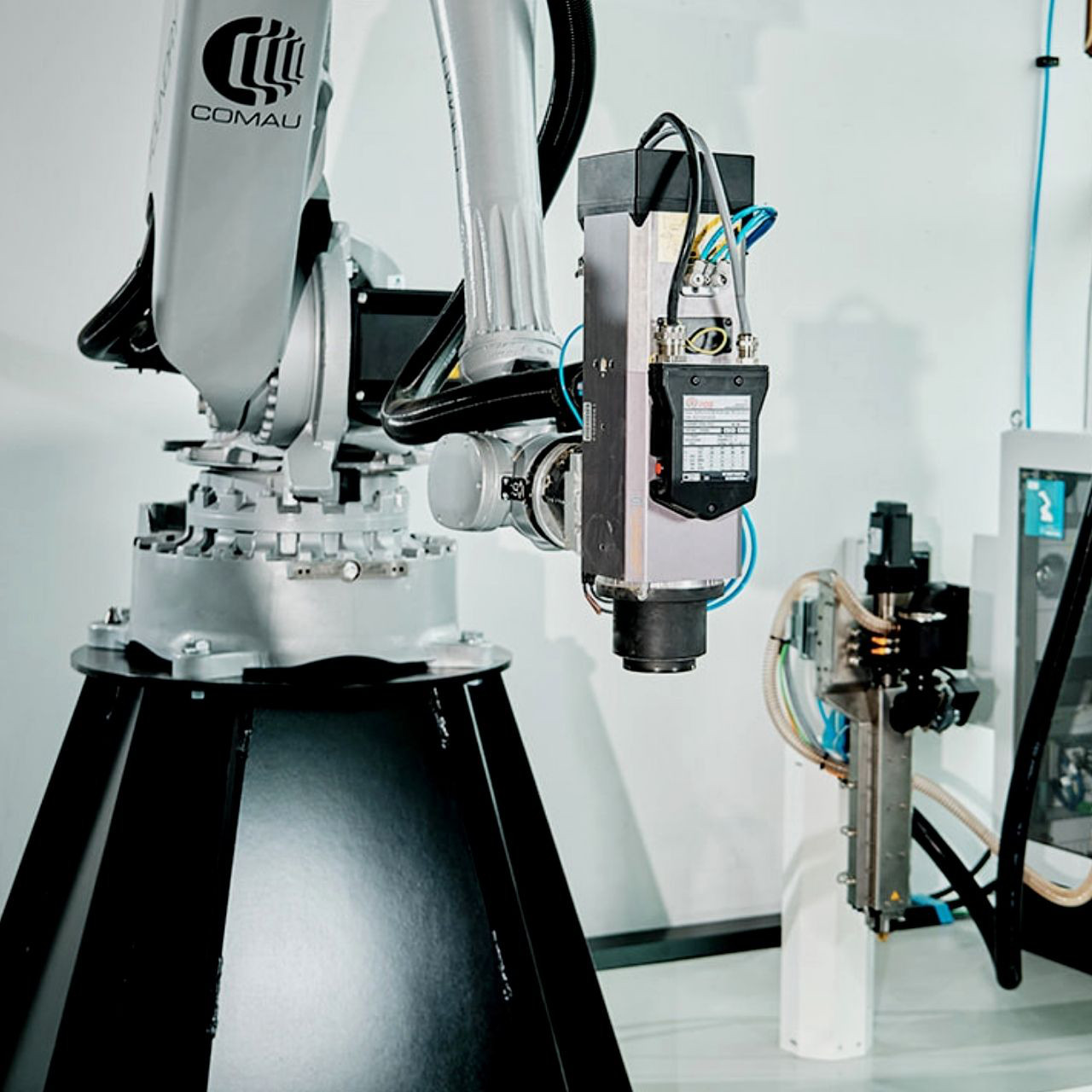

CEAD offers various possibilities for large scale 3D printing training. The most common training is the obligatory training that comes with the purchase of the Flexbot. Besides this training focused on our robot solution for 3D printing, CEAD also offers optional training for their pellet extruders.

The content of the pellet extruder training and how it is conducted differs based on the preferences of the client. CEAD is able to provide the training through an online call, at our production hall, or on-site. The current article elaborates on the training that is given to new owners of the Flexbot solution.

Specifications of the Flexbot training

CEAD does not differentiate between starters, advanced or other types of training, all clients receive the same level of training. However, the training is personalized as much as possible. Think for example of engineers that are familiar with CNC machines, who require different/less training than people who are new to the machinery.

Generally, the training is followed by up to 5-6 persons. This is due to the ideal trainer-to-trainee ratio of 1 to 3. Flexbot training is usually conducted by two application/customer support engineers. In our experience, a maximum of three persons per trainer provides the optimal experience for the trainees. If necessary, on request it is possible to provide training with a higher capacity.

Contents of the Flexbot training

The training for the Flexbot can be divided into three different components: an online part, a visit at CEAD, and on-site training at the client’s preferred location.

1. Online course

The first part consists of an online course concerning the Flexbot, which clients can complete in their own time. The video course covers various topics, such as:

- Information on the driver: G-code.

- An elaboration on the system behind the machine.

- How to design for large scale additive manufacturing as opposed to smaller 3D printing machines or CNC machines.

- Design cases that can be completed online.

- An introduction to Siemens NX, the software which enables CAD modeling, advanced slicing operations, bead modeling, simulations and, advanced milling operations.

2. In-house training

Once this course is completed, the client is invited to get to know the machine at our production facility. During this visit, we discuss the various buttons and functions of our Flexbot. This training focuses on the ‘hands-on’ aspect, clients are encouraged to use the Flexbot themselves. During the visit, our application and support engineers will provide an in-depth overview of the hybrid manufacturing capabilities of the Flexbot and Siemens NX. The content is revised multiple times during the visit, ensuring optimal retention.

3. On-site training

After one week of working with the Flexbot in Delft, the training continues with the final part which takes place on-site. At the start of this training, CEAD installs the Flexbot in the production facility of the client. During these 2-3 days of training, the role of our engineers is more spectating than instructing. They will only intervene with 3D printing activities if they see possible improvements. This part of the training is mostly concluded in order to give the client optimal confidence in the usage of the Flexbot.

After completion of the training

The main target of the training is to instruct new customers of an Flexbot in optimal usage, resulting in confident printing and milling. Clients gain a better understanding of the printer after completion of the training.

CEAD’s training functions more as an introduction into large scale additive manufacturing as opposed to a full scale production training. Clients are advised to gain experience with the Flexbot by themselves in order to continue the learning process. This valuable experience is not something that we can transmit through the reserved time for training.

Clients are provided with a complete package of video documentation after the training. Answers to frequently asked questions are found in these videos, as well as an overview of the content of the training. Also, the customer support department will support the client if any questions arise after the completion of the training.

Schedule a large scale additive manufacturing training

While the Flexbot training is obligated for all new Flexbot users, CEAD also provides complimentary training for our pellet extruders. The pricing of these training depends on the requirements listed by our clients. Are you interested in receiving more information on a large scale additive manufacturing training from CEAD? Please feel free to contact us for additional information or personalized training.

An excellent insight in training can be found in the review on a pellet extruder training below by Xabier Pérez Ferrero of Aimen Centro Tecnológico.

“We traveled to the CEAD Group factory to conduct a 3 day training concerning the robot extruder printing system. During the first of the three days, we got the chance to test the purchased equipment as well as to conduct the training section regarding material testing which enabled us to distinguish between the inherent characteristics of each material and how to use the equipment with each of them since the behavior of every material is different. Also, we were taught how to identify each material’s inherent process parameters.The second day of the training was dedicated to designing for large scale additive manufacturing, which was of vital importance since 3D printing with a high output pellet extruder completely changes the rules of traditional 3D printing. Also, it is mandatory to know the peculiarities of the process in order to achieve successful prints.

On the third day, we focused on the printing process itself, learning the basics of robotized large AM, like achieving optimal build surface adhesion, different deposition strategies, identifying, and solving process defects and safety measures.

In conclusion, we got the necessary skills to feel confident to safely operate CEAD equipment, which otherwise would have been a long arduous path of trial and error with the risk of damaging the equipment and ourselves. The training had significant importance since it allowed us to see all the issues that will always arise eventually with our own eyes. Additionally, having the guys from CEAD by your side guiding you on how to proceed to overcome these adversities with a full hands-on experience will save you a lot of time of headaches and down-time of the equipment. Fully recommended.”