In recent years, the Netherlands has become one of the trailblazers in maritime technology, specifically with its adoption of large format 3D printing in boat manufacturing. This innovative approach to shipbuilding transforms the traditional industry and opens new possibilities for design, efficiency, and sustainability.

In this blog post, we will explore the fascinating world of boat 3D printing in the Netherlands and how this cutting-edge technology is revolutionizing the maritime landscape.

Advantages of 3D printing for boat manufacturing

The Netherlands, widely known for its rich maritime history, stands at the forefront of a groundbreaking technological shift. Focusing on the implementation of large format 3D printing, emphasizing the use of sustainable materials, several key players are pioneering this technological shift.

One of the most significant benefits of manufacturing a boat with 3D printing is the freedom it provides from design constraints. Traditional shipbuilding methods often rely on complex-shaped and expensive molds and tooling, which require high upfront costs. With 3D printing, intricate and customized boat designs are achievable without these upfront expenses, allowing naval architects to explore new possibilities to push the boundaries of aesthetics and functionality.

The process of 3D printing minimizes waste production, enables the use of eco-friendly recycled materials and reduced overall energy consumption, aligning perfectly with worldwide environmental goals. 3D printing boats therefore poses as an ideal manufacturing method in a time where sustainability is top priority.

The rise of boat 3D printing is not isolated; it thrives in collaborative ecosystems and innovation hubs. Shipbuilders, technology firms, material suppliers, print services and research institutions work hand in hand, fostering an environment where ideas are exchanged, tested, and refined. This collaborative spirit propels the industry forward, ensuring the latest advancements are swiftly integrated into the boat 3D printing landscape.

Examples of 3D printed boats

Some great examples of the advancements and results of 3D printing boats are the following.

One of the first examples of manufacturing a boat with large format 3D printing went viral in 2019. The 3D-printed boat by the University of Maine, was a great showcase for inspiring the world of what can be achieved manufacturing using this technology in the maritime sector.

Figure 1: University of Maine 3D printed boat

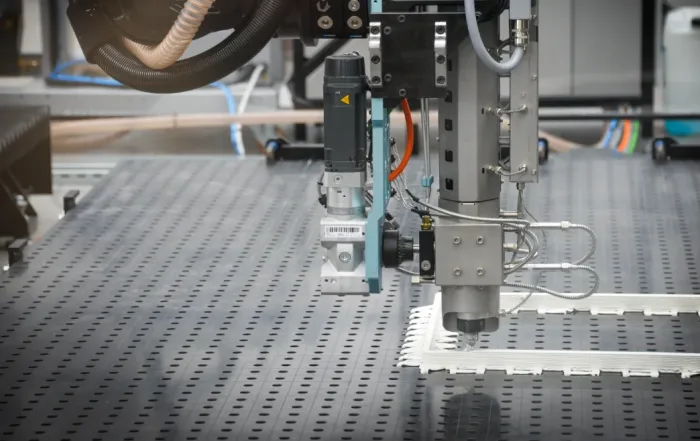

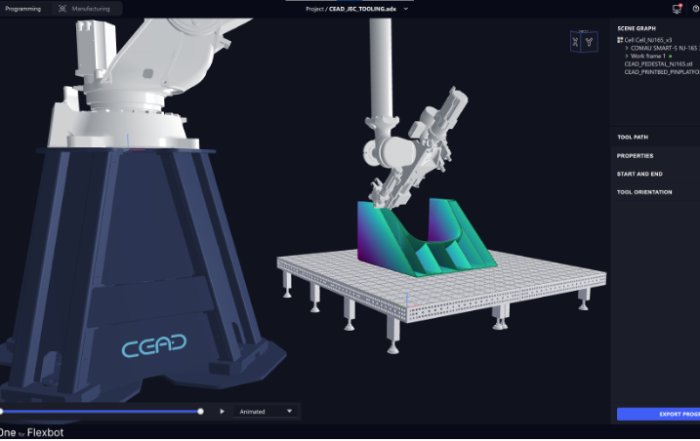

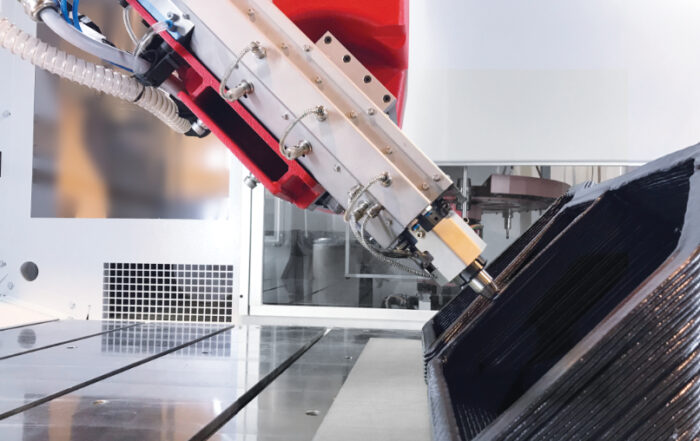

Al Seer Marine printed a 11.98m long ferry in Abu Dhabi. This is the largest printed vessel so far. The material was a recycled PET-G from MCPP. Using the custom-made Flexbot robotic 3D printer for printing the vessel. This machine can print boats up to 36 meters long.

Figure 2: Source Al Seer Marine & ceadgroup.com

Figure 3 source: Al Seer Marine & ceadgroup.com

IMPACD boats from the Netherlands have been on the forefront of 3D printing boats from recycled materials. The company has partnered with several Dutch 3D printing services such as Royal 3D and 10XL. They place a strong emphasis on sustainability within the maritime sector, going beyond the use of recycled materials for the hull. Their commitment extends to the selection of eco-friendly materials for the boat’s finishing and they’ve even embraced an entirely electric propulsion system. Their comprehensive approach truly makes an impact on the sustainability 3D-printed boat manufacturing.

Figure 4: Source Impacdboats.com

Another recent development is the 3D-printed autonomous ferry for the Olympic games in Paris. The 3D printed boat has been commissioned by Holland Shipyards group and was created by print service 10XL using a robotic 3D printer. This illustrates a great example of collaboration between several companies in the Netherlands, accelerating the adoption of 3D printing for the maritime industry.

Figure 5: Source 10-XL.nl

3D printing technology in boat manufacturing

All the above examples are great showcases of materials, boat design, experience and large format additive manufacturing technology coming together.

It clearly illustrates that the implementation of 3D printing technology in boat manufacturing is on the rise. Huge advancements have been made in terms of materials, designs, machinery, and suppliers. Really investigating and inspiring what can be done. Would you be interested in the manufacturing of 3D printed boats? CEAD has an extensive network of contacts that build wonderful experiences in this field. Being a key player in terms of the required hardware and software, having many partners that make use of our technology or shared experience.

Continue reading on large format additive manufacturing

Three groundbreaking world conquerors nominated for 39th edition Rotterdam Entrepreneur Award

This article was originally written in Dutch, click to read the original version in DutchCEAD,Van Donge & De Roo and Hollandia Services are the finalists of the Rotterdam Entrepreneur Award 2024. The nominees for the [...]

What staff do you need for large format additive manufacturing (LFAM)?

When it comes to implementing a new technology, involving employees during the adoption process is essential. While our large format 3D printing solutions focus on automation, people are still a crucial element. With new [...]

3D Printing in boat manufacturing

In recent years, the Netherlands has become one of the trailblazers in maritime technology, specifically with its adoption of large format 3D printing in boat manufacturing. This innovative approach to shipbuilding transforms the traditional [...]

CEAD and ADAXIS Integration Redefines Efficiency in Robotic Large Format 3D Printing

JEC World Paris, 5th March, 2024 - CEAD, frontrunner in robotic large format 3D printing solutions, is thrilled to announce a pivotal collaboration with ADAXIS, a rapidly fast-growing robotics software company. This strategic partnership aims to strengthen [...]

Large format 3D printing with PIPG

If you are looking for a cost-effective, easy to use and beautiful printing material for your large format 3D printer, PIPG is the right material. PIPG, or Post-Industrial PET-G, is an innovative recycled material [...]

3D printing with pellet extruders versus with filament

In all processes of industrial manufacturing, efficiency is key, and speed is paramount. Industrial 3D printing helps companies to improve and speed up their manufacturing processes by rapid prototyping, unlocking fast customization and by [...]