CEAD’s large scale 3D printing technology uses thermoplastics. Thermoplastics are plastics that, after applying a specific heat, melt and can be reformed. These thermoplastics are used to a great extent in other processes such as injection molding, plastic extrusion, rotational molding, vacuum forming and in small scale printing such as FDM (extrusion based process) and SLS (laser Sintering process). In this blog we will tell you more about the characteristics of 3 commonly used thermoplastics for large-scale 3D printing. In our next blogs we will discuss even more commonly used materials.

One can imagine that using the same material characteristics for injection molding as well as for 3D printing might not be the best idea, as processing conditions are completely different. For starters injection molding is done in a completely closed and controlled environment, in this case often referred to the mold itself. While large scale 3D printing is characterized by having a bigger, often open and less controlled environment, in which material is laid out in a different way each time. So while we should not expect to be able to use all injection mold grade materials without any challenges for 3D printing, we can ofcourse use the extensive knowledge in this industry about the suitability of specific thermoplastics for applications.

Three commonly used thermoplastics materials for large scale 3D printing we discuss in this article are:

- PET

- PLA

- PP or Polypropylene

1. Benefits and weaknesses PET

Most plastic bottles are made from PET. However, many different PET grades are available. PETG is an amorphous PET grade which works well for 3D printing generally speaking. PET is more challenging than other thermoplastics and in most cases semi crystalline, but holds the potential for very nice properties such as good thermal resistance, works generally well with coatings and adhesives, and can often be finished to a very smooth finish by using either milling, grinding or sanding.

PET and PETG often demonstrate better outside performance when compared to, for example, PP. In a lot of cases coating systems applied to thermoset materials can be used for these materials as well.

PET and PETG show, like many other thermoplastic materials, hygroscopic behavior. This means that the materials take up moisture from the air, and therefore need to be pre dried before processing. PET and PETG allow relatively large amounts of moisture between their polymeric chains which makes the drying essential. Make sure to have a good dryer installed as insufficiently dried compounds will degrade faster during processing and it will drastically increase the change on voids and other inconsistencies.

Most PETG and PET compounds degrade quickly when being in molten state for extensive periods of time. Make sure to reduce residual times of the compound in your extruder as much as possible.

Have a look at the datasheet of the PET GF material we tested with our machines for an overview of all specifications.

Have a look at the datasheet of the PET GF material we tested with our machines for an overview of all specifications.

2. Benefits and weaknesses PLA

Plastics that are derived from biomass (Polylactic Acid or PLA) are known as biobased polymers. PLA is very widely used in smaller scale 3D printing. The processing of the material is in most cases very good. Mechanical performance of most biobased materials is often lower compared to the synthetic counterparts. However many companies are working on changing this.

For printing on a large scale, often fibers are added to make these biobased materials perform better. Cellulose fibers for example, drastically increase performance. Although the material still does not compare to synthetic materials with glass or carbon, it shows properties already good enough for many applications. For larger scale 3D printing it is often used in combination with cellulose fibres which makes for a nice alternative to synthetic thermoplastics.

Some PLAs are not ideal for outside use and should be coated before outdoor usage. However, the UPM Formi compound has proven to be very reliable in outdoor applications. Like PET and PETG, most PLAs are also hygroscopic and should be dried before usage. Another thing to keep in mind when working with PLA, is that most PLA compounds degrade quickly when being in molten state for extensive periods of time. Because of this, you should make sure to reduce residual times of the compound in your extruder as much as possible.

Have a look at the datasheet of the PLA material we tested with our machines for an overview of all specifications.

Have a look at the datasheet of the PLA material we tested with our machines for an overview of all specifications.

3. Benefits and weaknesses of PP (or Polypropylene)

PP or Polypropylene is a commodity thermoplastic often used for lightweight applications with excellent chemical resistance. It is used by many different industries and because of that, PP is one of the materials that has many different grades and compounds, and has been developed for many different applications. However the material is harder to coat in most cases, it is not impossible: car bumpers are in most cases made from PP.

Many materials show rapid degradation after extensive periods of being in molten state, PP is one of the materials where this degradation process shows very slowly making it a relatively user friendly material during processing. And while we just learned PET, PETG and PLA are hygroscopic, PP is not. PP is one of the few materials that does not demonstrate this behaviour and so, does not require a dryer. Also keep in mind that PP has a poor intrinsic resistance against UV. To make sure the material is suited for outdoor applications as well, additives can be used.

When extruding PP, a minimum amount of VOCs is emitted during the process which also makes it one of the safer materials to work with. Still make sure to check the MSDS when processing and keep a VOC indicator at hand to make sure critical levels are not exceeded. These characteristics make PP into a good material for testing and for starting building experience with large scale 3D printing.

One of the downsides of the material is that PP shows a lot of shrinkage during processing, making it hard or impossible to print with most PP compounds. Only some PP compounds have proven to work well with large scale 3D printing.

Have a look at the CEAD Basic Allround – PP 30% Glass Fiber datasheet to see the official specifications of the material for injection molded tensile test specimens.

Have a look at the CEAD Basic Allround – PP 30% Glass Fiber datasheet to see the official specifications of the material for injection molded tensile test specimens.

Benefits of other thermoplastics and expected printing behavior

So while PP is an excellent material for lightweight, larger applications, PLA is mostly used for smaller scale 3D printing, and PET knows a wide variety of applications. Where PLA, PET and PETG show hygroscopic behavior and rapid degeneration after extensive periods of being in molten state, PP does not, and therefore makes a great material for testing. Of course, this is only a compact overview of three out of many thermoset materials. Research about the composition and use of different thermoplastics is still ongoing and will give us more knowledge and expertise every day. In our upcoming blogs we will elaborate more on other materials and need-to-knows.

Curious about a all the materials we have tested with our machines and clients? Check our material page. Or read more about the expected behavior of thermoplastic while 3D printing, to prevent deformation issues like shrinkage.

Would you like to know more about one of our machines or material, don’t hesitate to contact us. We are happy to think along!

Feel free to call us: +31 (0) 15 737 01 83

Or send an email to: info@ceadgroup.com

Continue reading on large format additive manufacturing

Three groundbreaking world conquerors nominated for 39th edition Rotterdam Entrepreneur Award

This article was originally written in Dutch, click to read the original version in DutchCEAD,Van Donge & De Roo and Hollandia Services are the finalists of the Rotterdam Entrepreneur Award 2024. The nominees for the [...]

What staff do you need for large format additive manufacturing (LFAM)?

When it comes to implementing a new technology, involving employees during the adoption process is essential. While our large format 3D printing solutions focus on automation, people are still a crucial element. With new [...]

3D Printing in boat manufacturing

In recent years, the Netherlands has become one of the trailblazers in maritime technology, specifically with its adoption of large format 3D printing in boat manufacturing. This innovative approach to shipbuilding transforms the traditional [...]

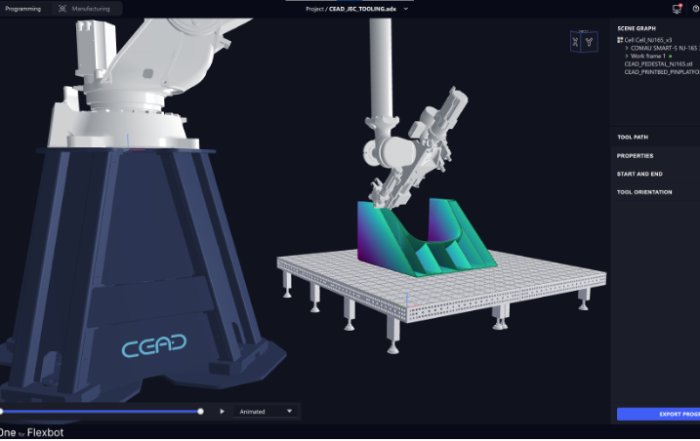

CEAD and ADAXIS Integration Redefines Efficiency in Robotic Large Format 3D Printing

JEC World Paris, 5th March, 2024 - CEAD, frontrunner in robotic large format 3D printing solutions, is thrilled to announce a pivotal collaboration with ADAXIS, a rapidly fast-growing robotics software company. This strategic partnership aims to strengthen [...]

Large format 3D printing with PIPG

If you are looking for a cost-effective, easy to use and beautiful printing material for your large format 3D printer, PIPG is the right material. PIPG, or Post-Industrial PET-G, is an innovative recycled material [...]

3D printing with pellet extruders versus with filament

In all processes of industrial manufacturing, efficiency is key, and speed is paramount. Industrial 3D printing helps companies to improve and speed up their manufacturing processes by rapid prototyping, unlocking fast customization and by [...]